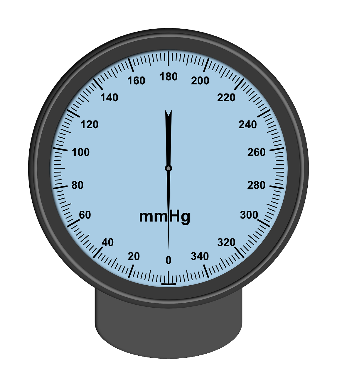

Pressure gauge

Instrument for measuring the condition of a fluid (liquid or gas) that is specified by the force that the fluid would exert, when at rest, on a unit area, such as pounds per square inch or newtons per square centimeters

Pressure gauges are used to determine

- Steam Pressure

- Feedwater Pressure

- Oil Pressure

- Gas Pressure

- Draft Pressure

- Boiler temperature gauges

Pressure gage is commonly classified as three types as the following below:

- Bourdon pressure gage

The bourdon pressure gage is type pressure gage which has bourdon tube, it’s an oval cross section of hollow tube. The tube has two ends, open and close. Open end is connected to fluids either water or steam and close end is connected to mechanical linkage in gage pointer. When the pressure builds up, the bourdon tube will be straightened out.

- Bellow pressure gage

This type is commonly applied for the pressure under 30 psi.

- Spiral pressure gage

The spiral pressure gage is modification design from bourdon pressure gage type. It has spiral and long pressure sensing.

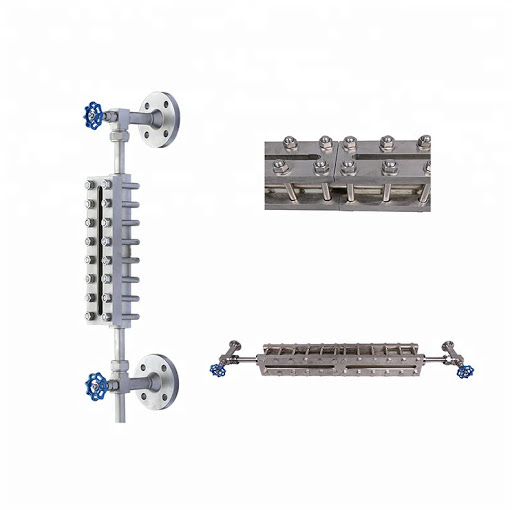

Gauge Glass

A gauge glass shows the current level of water in the boiler, regardless of the boiler’s operating conditions. Gauge glasses should be installed so that their lowest reading will show the water level at 50 mm above the point where overheating will occur. They should also be fitted with a protector around them, but this should not hinder visibility of the water level.

Level gauge

Level gauge consists of a metal body, machined to have an internal chamber and one or more front windows. On each window a special high resistance glass is used with sealing joint and metal cover plate hold by bolts and nuts

Features of Level Gauges

- Completely mechanical device

- Doesn’t require power to operate

- Mostly used for visual level indication

Glass Type Level Gauges

- Tubular Level Gauge (TTG)

- Reflex / Transparent Flat Glass Level Gauge (RFG & TFG)

- Transparent gauge

Float Type Level Gauges

- Magnetic Level Gauge (MLG)

- Float and Board Gauge (FBG)

- Float & Tape Gauge (FTG)

- Float & Dial Gauge (FDG)

Conductivity Meter

A conductivity meter measures the amount of electrical current or conductance in a solution. Conductivity is useful in determining the overall health of a natural water body. It is also a way to measure changes in wastewater procedures at water treatment plants. Conductivity meters are common in any water treatment or monitoring situation, as well as in environmental laboratories.

Contacting-type conductivity meter

The contacting-type conductivity sensor usually consists of two electrodes, insulated from one another. The electrodes, typically 316 stainless steel, titanium-palladium alloy or graphite, are specifically sized and spaced to provide a known “cell constant.” Theoretically, a cell constant of 1.0 describes two electrodes, each being one square centimeter in area and spaced one centimeter apart.

Electrodeless type conductivity meter

The electrodeless type of conductivity sensor operates by inducing an alternating current in a closed loop of solution and measuring its magnitude to determine conductivity. The conductivity meter drives Toroid A, which induces the alternating current in the solution. This AC signal flows in a closed loop through the sensor bore and surrounding solution. Toroid B senses the magnitude of the induced current, which is proportional to the conductance of the solution. This signal is processed in the meter to display the corresponding reading.

Total Dissolved Solid (TDS) Meter

A total dissolved solid (TDS) is a measure of the combined total of organic and inorganic substances contained in a liquid. This includes anything present in water other than the pure H20 molecules. These solids are primarily minerals, salts and organic matter that can be a general indicator of water quality. High TDS generally indicate hard water, which can cause scale build up in pipes and appliances. Scale buildup reduces performance and adds system maintenance costs.