WoodChip Dryer Machine

“Wood chops at high humidity will reduce their combustion efficiency. which causes incomplete combustion causing a lot of pollution, both soot, And more ash, the Woodchip Dryer is an option to optimize fuel combustion.”WoodChip Dryer machine WoodChip Dryer machineries

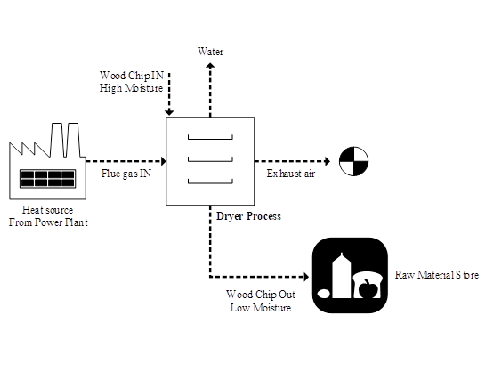

- Use residual heat from biomass power plants To be a heat source in the dehumidification process of chopped wood.

- The initial moisture content of the wood chips is more than 50 percent, the final moisture content of the wood chips is less than 30 percent.

- There is a system to remove water caused by the condensation of hot steam.

- Dehumidification system for continuous wood chipping suitable for power plants This is because it can produce enough wood to be used as fuel to meet the needs of the power plant.WoodChip Dryer machineries

WoodChip Dryer Machine

The benefits of wood chips are less moisture.

The calorific value of the fuel depends on the moisture content of the wood chips, which varies according to the type of wood. Fresh wood has a moisture content of 55% and is capable of generating electricity at 2000 kWh per 1000 kg of wood. When the humidity of the wood chips is reduced by 20%, the heating cost of the fuel is doubled and it can generate electricity. At 4000 kWh per 1000 kg of wood, the wood-powered steam boiler is more efficient and stable when fueled with wood chips at low humidity. and can also increase the maintenance period of the combustion process in addition, wood chips with a moisture content of more than 30 percent tend to be easily damaged by natural conditions.

Benefits of a dehumidifier

– Increase the efficiency of production and transportation processes.

– Adds value to wood chops at low humidity.

– Chopped wood at low humidity is easy to store and maintain.

Benefits of Dryer Processes

- Reduce the cost of production in terms of fuel Because when the fuel has reduced moisture content. This shows that such fuel can be converted to heat energy almost 100%.

- Saves heat energy supplied to the combustion system due to incomplete combustion processes. (Moisture fuel) has a higher fuel demand than usual. Because part of the heat is required to evaporate moisture from the biomass. and then the combustion process takes place.

- Increased service time of dust collection systems (ESP) due to high humidity of biomass resulting in incomplete combustion. bring about a large amount of carbon remaining in the system. This affects the efficiency of the fuel gas dust collection system before releasing it into the environment.

- Environmental promotion because it reduces the amount of dust released into the community and nature.

- Fuel dehumidification process size It can be adapted to suit the needs of the biomass power plant size.